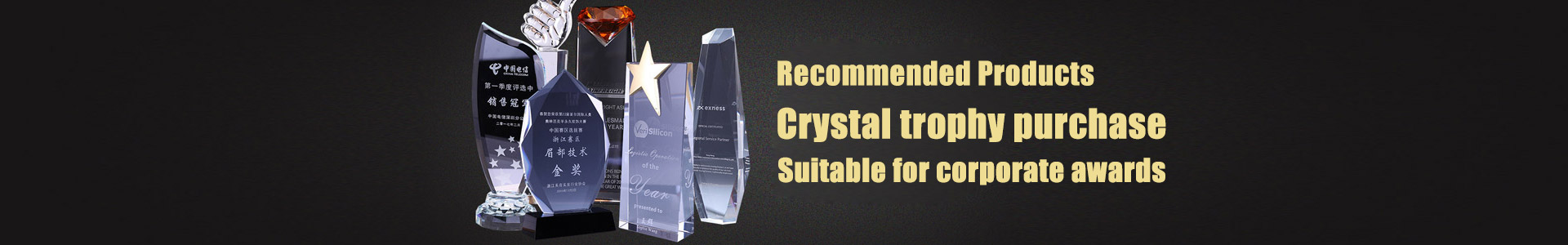

Crystal trophy is a symbol of noble purity, often used in government and business awards. It is crystal clear, sparkling and delicate in touch, and can also be lettering and pattern on it. The material used is crystal clean like ice and snow. It's great to use it to make prizes for good people.

Use occasions: advertising promotions, conference celebrations, office benefits, thank customers, holiday celebrations, housewarming, graduation, college supplies, souvenir collections, etc.

Production process: raw materials, cutting, sanding, sandblasting, internal carving, assembly.

There are a total of production processes: material selection, material opening, blank pressing, rough polishing, fine polishing, punching, color plating, carving, sandblasting, viscose, quality inspection, and packaging.

1. Material selection: Crystal raw materials are usually divided into several grades, preferably no impurities, provisions and bubbles, the material is also very regular, the brightness is very high, very transparent, and in turn, there are small defects.

2. Opening: It is the shape and size required to cut the entire piece of material with a large saw blade at high speed.

3. Embossing: The required size and shape of the finished product are made with a mold, and the raw materials are heated to a temperature above 900 ° C to melt, flow into the mold, and die-cast.

4. Rough polishing: The blanks pressed out from the mold are directly ground with diamond discs to cut the finished product.

5. Fine polishing: After rough polishing, polish the finished product with polishing powder until it is crystal clear.

6.Punching: Before the finished crystal is finished, punch the hole with a drill according to the size and position of the required punching.

6. Silk screen: different color materials are attached to the surface of the crystal for effect treatment, the color layer is thicker, and it can fall off after focusing.

7. Color plating: using a similar plating method on the surface of the crystal with different colors, thin layers, can be scratched by friction, scratches occur, because the color plating is often located at the bottom, so other objects are often attached to the bottom of the color plating Such as the zodiac Wenzhen.

8.Carving: strong three-dimensional sense, high technology, fine workmanship and high cost. Divided by hand carving graphics, machine carving text.

9. Sandblasting The film is coated on the surface of the crystal through a special medium, and then the surface of the crystal is impacted by the machine with different thicknesses of sand to form the pattern required by the customer.

10. Assembly Some crystals are composed of several parts. Here I need to assemble all the accessories. This is a meticulous work, and a little carelessness will make the entire product scrap.

11. Packaging: Scrub the crystal trophy and put it into a specially made brocade box. This is a finished product.

12: The above are only the processing procedures of most crystals. For some crystals, such as: round, polygonal, concave, and carved crystal, there are special processing methods.